Well, Zina and I were heading to a track day and with the 916 approaching the 10,000 mile mark, I wanted to be sure the timing doesn't radically alter all by itself.

I removed the drive pulley's nut to slide off the V cylinder's drive pulley, but that ended up being unnecessary.

I've twice since changed the belts. It seems I let them go about 6000 miles and they shread a bit on the edges, so they are replaced overly frequently.

Hey, you two valvers out there: be prepared to spend some time changing belts on a 4 valver.

You've got to take off the fairings, seat, fuel tank, air box, battery, and misc electricals on the right side to access the belt covers.

I'd bill this as a 3 hour job, where 2Vs would be 1.5 hours.

Note: although it is evident in the pictures below that I removed the drive pulley nut (in the Vee), this is not required to change the belts.

They'll slip off the pulley with the tensioners completely loosened.

(As copied from my 4V maintenance page) Superbikes have an issue with the belt tensioner locknuts.

It seems that not all dealers or mechanics replace the lock muts with every use.

6mm locking flange nuts are available via any fastener supply house for a reasonable cost.

There is no excuse for one of these to work loose and alter your timing because your maintenance guy is lazy.

It's kind of a bear getting in there to set and lock the 4V belt tensioners, especially since the rear cylinder is behind the frame.

There are two tools that nicely do the job: Snap-On's FHOM12 and XBM2224A 12mm socket and 22/24mm offset wrenches.

|

Apparently, the factory started using belts with kevlar woven in them for racing.

It was discovered they were better and could rev higher, then started supplying all 4V belts as these.

Look for the red lettering.

See that 58095 number?

That 095 seems to be the number of teeth on the belt.

More below...

|

|

I had a bit of an epiphany changing the 916's belts today... a merging of a flashback of timing the cams on a KZ650 and changing the 2V belts.

There are a set number of teeth between the alignment dots.

If you count these teeth while aligned, you could mark the teeth of the new belts to make their installation much easier.

|

|

|

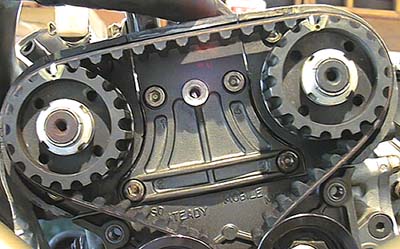

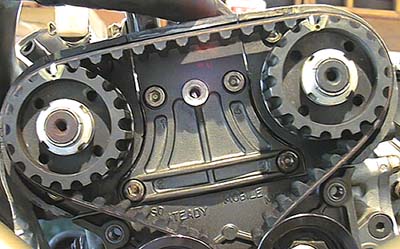

The vertical cylinder has 12 teeth from one timing mark to the next - easily shown here.

Well, see the White Out (TM) marks on the new belt? Makes throwing it on a snap! Very quick to align the pulleys and belts to the timing marks on the head.

There are 38 teeth from the left pulley to the timing mark on the drive pulley and 45 from the right pulley's mark.

38+12+45 = 95

|

|

A quick alignment of the mark, slide the belt onto the pulley I didn't remove.

Notice that I marked the proper spot on the pulley, too.

Only the outside of the timing pulleys are dotted so I also marked the inside of the inner pulley.

|

|

|

Different timing marks are used for the horizontal and vertical cylinders.

Fortunately for me, the correct ones were already painted for me (from the factory?) The horizontal cylinder is done second and has 21 teeth from one timing mark to the next.

Here, there are 39 teeth from the top pulley to the timing mark on the drive pulley in the middle of the engine's Vee and 35 from the bottom pulley's mark.

39+21+35 = 95

|

|

|

A quick alignment of the mark, slide the pulley with belt on the shaft (sometimes the woodruff key even cooperates and stays in!) and tighten the nut.

|

As far as belt tension goes, a lot of people manually set tension.

I've used 5mm of play between the cam pulleys with moderate pressure using one finger.

I've heard of using 3mm of slack.

The factory tool clamps onto the belt and has a needle that sweeps across a numbered gauge without any units of measure.

Unfortunately, Ducati sells the tool for over $500.

Fortunately, I have found the makers of the tool and ofer it for under $300 at www.ca-cycleworks.com.

Click here for a pic: 4V Belt Tool

I've been told by some mechanics that the factory belt tool has much better repeatability and accuracy over trying to set the belts by hand or feel.